Forklift Truck Safety Signs-- Advertise Safe Practices and Mishap Avoidance

Forklift Truck Safety Signs-- Advertise Safe Practices and Mishap Avoidance

Blog Article

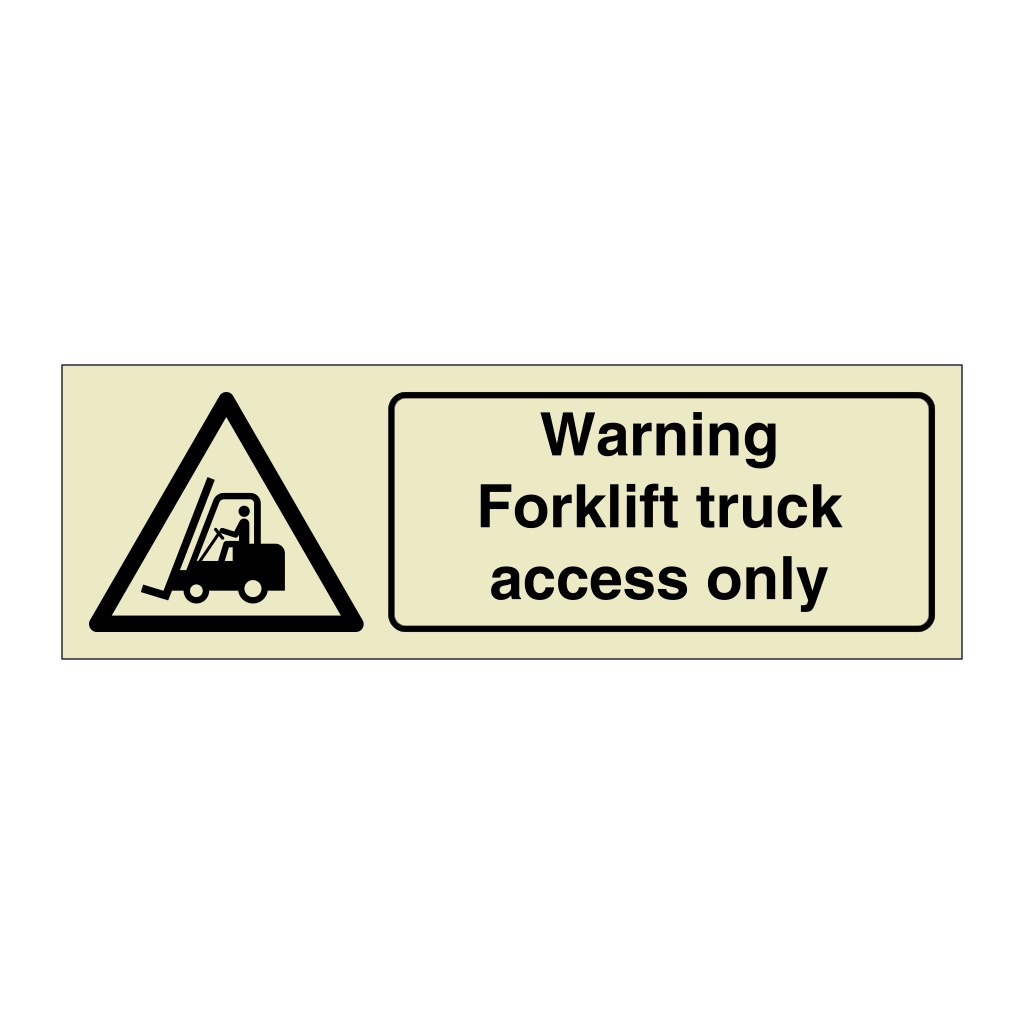

Forklift Safety And Security Signs: Necessary Tips for Optimal Positioning and Presence

Ensuring the optimum positioning and visibility of forklift security signs is crucial in maintaining a secure industrial atmosphere. Positioning these indicators at tactical places such as entrance and departure points of loading docks, essential facility crossways, and high-traffic storage areas can significantly alleviate accident dangers. Placing indicators at eye level and angling them towards oncoming web traffic enhances their effectiveness. Additionally, using durable materials and high-contrast designs ensures longevity and clearness. Recognizing the subtleties of routine examinations and upkeep is similarly important to support their capability-- what crucial steps should be taken to keep these vital security tools?

Key Locations for Security Signs

Appropriate positioning of forklift safety and security indications is important for keeping a safe workplace. Tactically positioned indications can significantly decrease the danger of accidents by supplying clear, immediate cautions and instructions to both drivers and pedestrians. Secret locations for these signs consist of access and leave points of filling docks, intersections within the center, and locations with heavy pedestrian website traffic. Furthermore, placing indicators near high-traffic storage locations and blind spots can better enhance exposure and recognition.

Crossways within the center are one more critical area where collisions can take place; as a result, stop indications and right of way signs are crucial. In pedestrian-heavy areas, indications ought to inform both operators and pedestrians to the presence of forklifts, guaranteeing everyone remains cautious.

Locations with high storage shelfs and blind spots position one-of-a-kind difficulties. forklift safety signs. Signs in these areas ought to warn drivers of restricted exposure and encourage using spotters or additional safety and security steps. By concentrating on these essential locations, organizations can develop a more secure, more effective workplace for all

Elevation and Angle Considerations

When setting up forklift safety signs, thinking about the elevation and angle of placement is important to guarantee optimum visibility and performance. Correct height makes certain that drivers and pedestrians can easily see the indications without blockage. Generally, safety indicators need to be placed at eye degree, which is approximately 4 to 6 feet from the ground. This placement permits individuals to swiftly notice and read the signs as they browse the area.

If an indication is indicated to alert forklift drivers, it should be placed directly in their field of sight, ideally perpendicular to their instructions of travel. In areas with numerous seeing angles, consider making use of double-sided indicators or tilted brackets to maintain presence from different directions.

In addition, ensuring that the indications are not blocked by various other objects, machinery, or shelving units is vital. Clear sightlines assist avoid accidents and improve overall security. By thoughtfully thinking about height and angle, you can significantly boost the performance of forklift safety signs, therefore promoting a safer job atmosphere.

Signage Product and Longevity

Picking the proper product for forklift safety and security indicators is essential for guaranteeing their longevity and performance. In environments where forklifts operate, indicators are commonly subjected to rough conditions, including physical effects, chemical spills, and differing temperatures. Choosing resilient products like light weight aluminum, high-density polyethylene (HDPE), and a knockout post polyvinyl chloride (PVC) can dramatically boost the signs' life expectancy.

Light weight aluminum is a preferred selection as a result of its resistance to corrosion and deterioration, making it optimal for both interior and exterior setups. Furthermore, its lightweight nature helps with simple setup and repositioning. HDPE is another robust choice, recognized for its exceptional resistance to chemicals and influence. It is specifically ideal for setups where chemical direct exposure is prevalent. PVC, on the various other hand, supplies an excellent equilibrium between sturdiness and cost-effectiveness, making it a common choice for many commercial atmospheres.

Additionally, the printing method used on these products additionally contributes in sturdiness. UV-resistant inks and protective laminates assist in protecting against fading and damages from sunlight and various other environmental variables. Sticking to these considerations makes sure that forklift safety and security indicators stay visible and clear over extended periods, thus maintaining a secure workplace.

Guaranteeing Indicator Presence

While picking resilient products for forklift safety indicators is necessary, guaranteeing their exposure is similarly crucial for maintaining visit the website a secure atmosphere. Efficient presence can be achieved via critical positioning, proper lights, and utilizing high-contrast shades. Indications should be positioned at eye degree and in places where drivers and pedestrians are probably to see them, such as at access factors, intersections, and areas with high web traffic.

Proper lighting is crucial to guarantee that indications are visible in all conditions. Setting up appropriate lighting in dimly lit areas or utilizing reflective materials on indicators can significantly enhance presence.

In addition, staying clear of visual mess around the signs is important. Way too many check in one location can bewilder and perplex people, decreasing the effectiveness of each sign. Clear, concise messaging and ensuring indicators are cost-free from obstructions such as equipment or storage space items will certainly additionally improve their presence and performance, adding to a much safer office atmosphere.

Regular Examination and Maintenance

Uniformity is crucial to preserving the effectiveness of forklift safety indicators, making regular evaluation and upkeep crucial. To make certain these indications continue to communicate critical details clearly, they must be consistently looked for wear and tear, fading, or blockage. forklift safety signs. Gradually, exposure to the components and operational activities can deteriorate learn this here now their visibility and clarity, undermining their purpose

An organized evaluation timetable should be developed, with checks conducted at normal intervals. Throughout inspections, evaluate each indicator's condition, making sure message and signs remain clear and lively. Any indications showing indicators of damage or fading must be promptly changed. Additionally, guarantee that indications are not covered by equipment, stock, or various other obstacles.

Conclusion

Correct positioning and visibility of forklift safety and security signs are essential in lessening work environment mishaps. Positioning indications at essential places such as access and exit points, center crossways, and high-traffic storage areas, while guaranteeing they are placed at eye level and tilted towards oncoming traffic, improves their efficiency.

Report this page